Borit's innovation in PEM bipolar plate production

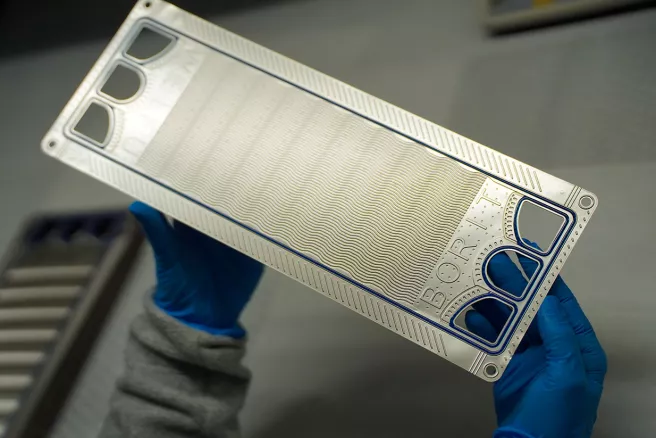

Borit stands at the forefront of manufacturing innovation, particularly in the realm of Proton Exchange Membrane (PEM) bipolar plate production, where the precision joining of two formed plates is often required.

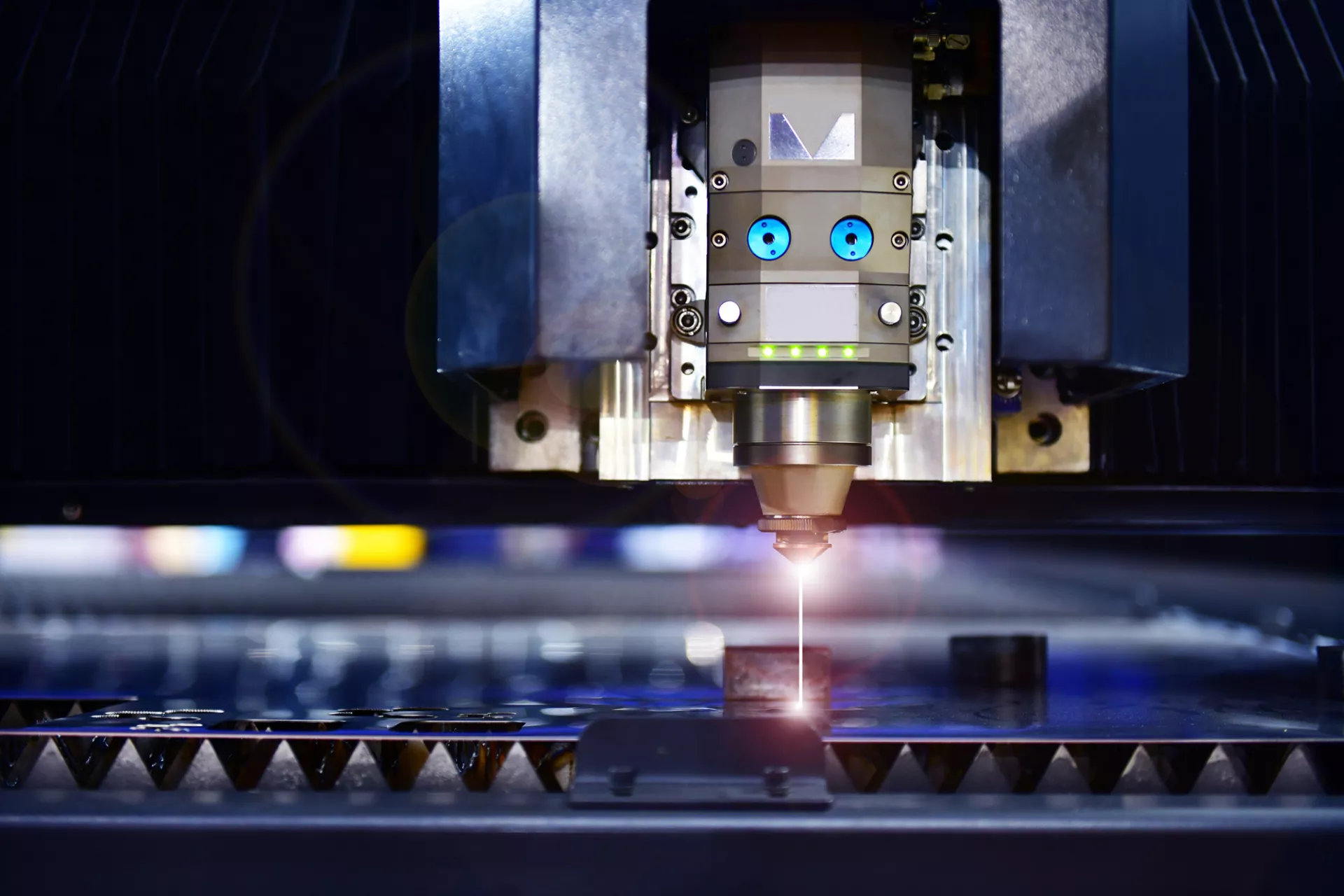

To address this critical need, Borit has harnessed state-of-the-art laser welding technology, creating a suite of assets designed to offer customers a solution that is not only high in quality but also remarkable in speed.

Precision, productivity and quality

At the core of this advanced capability is remote welding, employing the latest in fiber laser-welding technology.

This method provides a fusion of precision and efficiency, ensuring excellent welding quality that contributes significantly to the overall integrity and performance of the bipolar plates. Control over plate flatness during the welding process is meticulously maintained, a factor crucial in preventing warping and ensuring the plates meet stringent specifications.

Borit's laser welding technology excels in managing a high number of welds per plate, offering optimal productivity without compromising quality. This capability is particularly beneficial for projects requiring extensive welding work, enabling rapid production while maintaining high standards.

Precision welding with quality assurance

Further enhancing the value of our welding services, Borit incorporates integrated leak testing tailored to customer specifications. This critical step ensures that each welded plate undergoes meticulous evaluation for its integrity.

Through a series of rigorous tests customized to meet the unique requirements of each project, our integrated leak testing process guarantees the detection of any potential flaws or imperfections. By subjecting the welded plates to comprehensive examination, Borit ensures that the final product meets the highest standards of quality and reliability.

This commitment to thorough evaluation and quality assurance reinforces our dedication to delivering superior products that instill confidence in our customers and end-users alike.

From smaller to larger series productions

For projects with smaller production volumes, Borit offers manual welding operation options, allowing for flexibility and precision in small series production.

This approach ensures that even low-volume projects benefit from Borit's welding expertise.

Scaling up to meet the demands of medium to large series production, Borit employs automated assets and dedicates production lines specifically designed for these volumes.

This scalability ensures that as projects requirements grow, Borit's capabilities can seamlessly expand to provide consistent, high-quality welding services, making it an ideal partner for projects of any size.

Efficiency, quality, and precision

Through this comprehensive approach, combining cutting-edge technology with flexible production capabilities, Borit delivers unparalleled welding solutions for PEM bipolar plate manufacturing, supporting customers from small-scale projects to large-scale production with efficiency, quality, and precision.

Wherever our customers thrive, we innovate alongside them, aligning with their global footprint to deliver excellence right to their doorstep.