Cutting-edge solutions

Borit seamlessly integrates cutting-edge technology into its manufacturing processes to cater to a broad spectrum of industrial needs, offering both laser cutting and mechanical die cutting services tailored to the volume and specific requirements of our customers.

This dual-capability approach ensures that every project is matched with the most suitable cutting technology, optimizing both efficiency and quality.

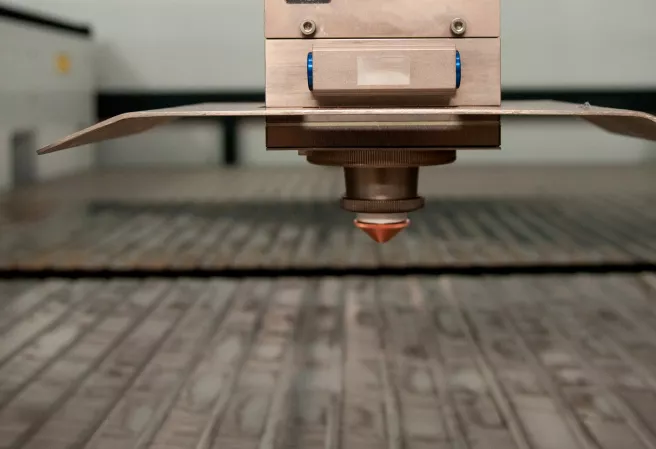

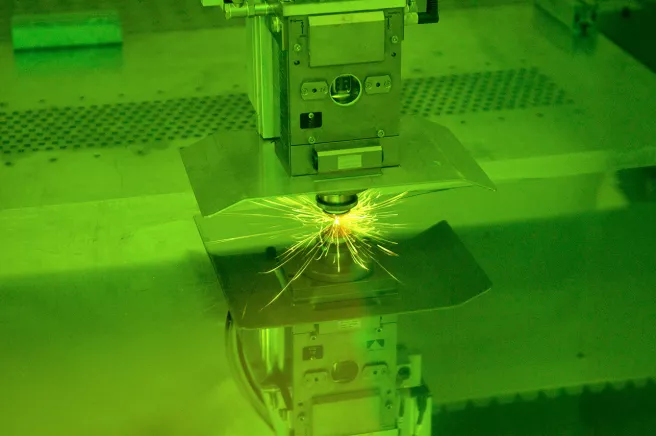

Laser cutting

Our laser cutting service is distinguished by its exceptional flexibility, making it an ideal choice for projects that demand precision and may require swift alterations or iterations in design.

Laser cutting technology for dynamic environments

This technology allows for fast design changes with minimal downtime, providing a significant advantage in dynamic development environments where speed and adaptability are crucial.

With laser cutting design-specific tooling and setup is rather simple, which not only lowers the initial costs but also accelerates the production timeline.

This makes laser cutting particularly effective for small to medium production series, where its ability to efficiently handle highly complex designs without the need for extensive retooling can significantly reduce overall project costs.

Moreover, for medium series production, the process can be easily migrated to an automated asset, enhancing throughput while maintaining the high quality and precision Borit is known for.

Mechanical Die Cutting

Mechanical die cutting, in contrast, excels in its ability to deliver high-quality cuts consistently over the tool's lifetime, making it a robust solution for medium to large series production.

This method leverages advanced tooling development techniques, ensuring optimized costs and high efficiency.

The precision and durability of the dies used in mechanical cutting mean that even at large volumes, the quality of the output remains uncompromised.

This approach offers optimal productivity for projects requiring significant output, providing a cost-effective solution without sacrificing the precision or quality of the finished product.

The capacity of mechanical die cutting to handle large orders efficiently makes it a valuable option for clients looking to scale production while keeping costs in check.

Dual-Cutting approach for every project

By offering both laser and mechanical die cutting, Borit positions itself as a versatile partner capable of adapting to the unique needs of each project.

Whether a client requires the agile precision of laser cutting for small to medium series or the robust efficiency of mechanical die cutting for larger volumes, Borit has the technology and expertise to meet and exceed expectations.

Wherever our customers thrive, we innovate alongside them, aligning with their global footprint to deliver excellence right to their doorstep.